The isotropic finishing makes it possible to improve the performances of the power transmissions durably. The effectiveness of this treatment has made it possible to apply it to a large number of sectors.

It is a process that makes the surfaces lucid by eliminating roughness through the action of erosion: the pieces are inserted in special tanks filled with acid with little invasiveness and granules with an abrasive power adequate.

The vibrating machinery allows these materials to gradually erode the surface of the parts. It is thanks to this graduation that it is possible to achieve the required roughness by adjusting the times and the speed and maintaining the geometries in any case.

The benefits of this type of treatment include:

- Surfaces with limited roughness which allow to have a higher efficiency, a reduction of friction, noise and temperature.

- Improvement of surface hardness.

- Absence of corrosion due to oxidation or high contact pressure.

- Lubrication better.

- Absence of accumulation of abrasive material in roughness.

- Improved fatigue characteristics.

- Absence of metallurgical degradation

- Increase to maximum levels with mechanical / thermal processes and resistance to surface tension

All these advantages ultimately involve longer parts life and a relative reduction in maintenance costs, in addition to the possibility of reducing or avoiding other treatments which would normally be required for the construction of the parts.

With this finishing, the high performances of the equipment are guaranteed, required especially in sectors where maximum precision is required, in addition to a remarkable aesthetic effect.

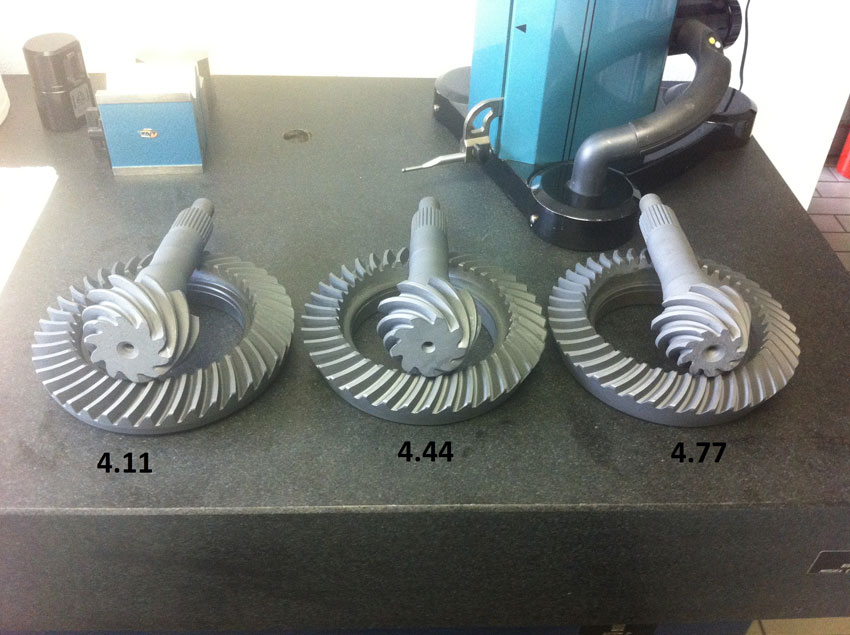

confronto tra n°3 coppie coniche di rapportatura diversa

confronto tra n°3 coppie coniche di rapportatura diversa